Introduction

In today’s competitive manufacturing landscape, efficiency and precision are key to success. A leading heavy-industry manufacturer in Japan faced challenges in managing their product lifecycle, from order placement to cost estimation. To modernize its operations, GITS developed a custom Product Lifecycle Management (PLM) system leveraging ARAS Innovator, AWS, Node.js, React.js, and Flutter.

This case study explores how GITS implemented a smart, scalable, and cost-effective PLM system, significantly improving efficiency, reducing manual processes, and enhancing data security.

The challenge: outdated systems hindering growth

The client, a heavy-industry manufacturer specializing in shipbuilding, heavy machinery, bridge construction, and aero-engine production, required a flexible and modern system to streamline their product lifecycle management. Their challenges included:

- Legacy system inefficiencies – Outdated systems with numerous manual processes slowed down operations.

- Scalability issues – The existing system lacked flexibility to accommodate future expansion.

- Budget constraints – A full-scale redevelopment was not feasible due to limited resources.

- Data security concerns – Heavy data processing required enhanced security and compliance measures.

GITS stepped in to provide a cost-effective, customized solution to overcome these challenges and future-proof the client’s manufacturing operations.

The solution: customizable PLM system with ARAS Innovator

To address the client’s needs, GITS implemented a tailored PLM system built on ARAS Innovator, an industry-leading PLM software known for its flexibility and ease of customization. Our solution consisted of:

1. Seamless order & estimation management

GITS developed a centralized system that digitized order processing, enabling easy management of customer requests, order tracking, and automated cost estimation to improve efficiency.

2. BOM (Bill of Materials) automation

A structured BOM management system was integrated, allowing manufacturers to create, modify, and track components throughout the production cycle. This feature eliminated errors and enhanced transparency.

3. Enhanced workflow automation & custom add-ons

Our engineers worked closely with the client to customize ARAS Innovator, developing workflow automation tools and user-friendly interfaces tailored to their specific business needs.

4. Secure cloud-based architecture

To support heavy data processing while ensuring security, we leveraged AWS cloud infrastructure, combined with Node.js and React.js for a scalable and high-performance backend.

5. Mobile access for on-the-go management

A Flutter-based mobile application was developed to provide real-time monitoring and order status tracking for managers and executives, increasing operational flexibility.

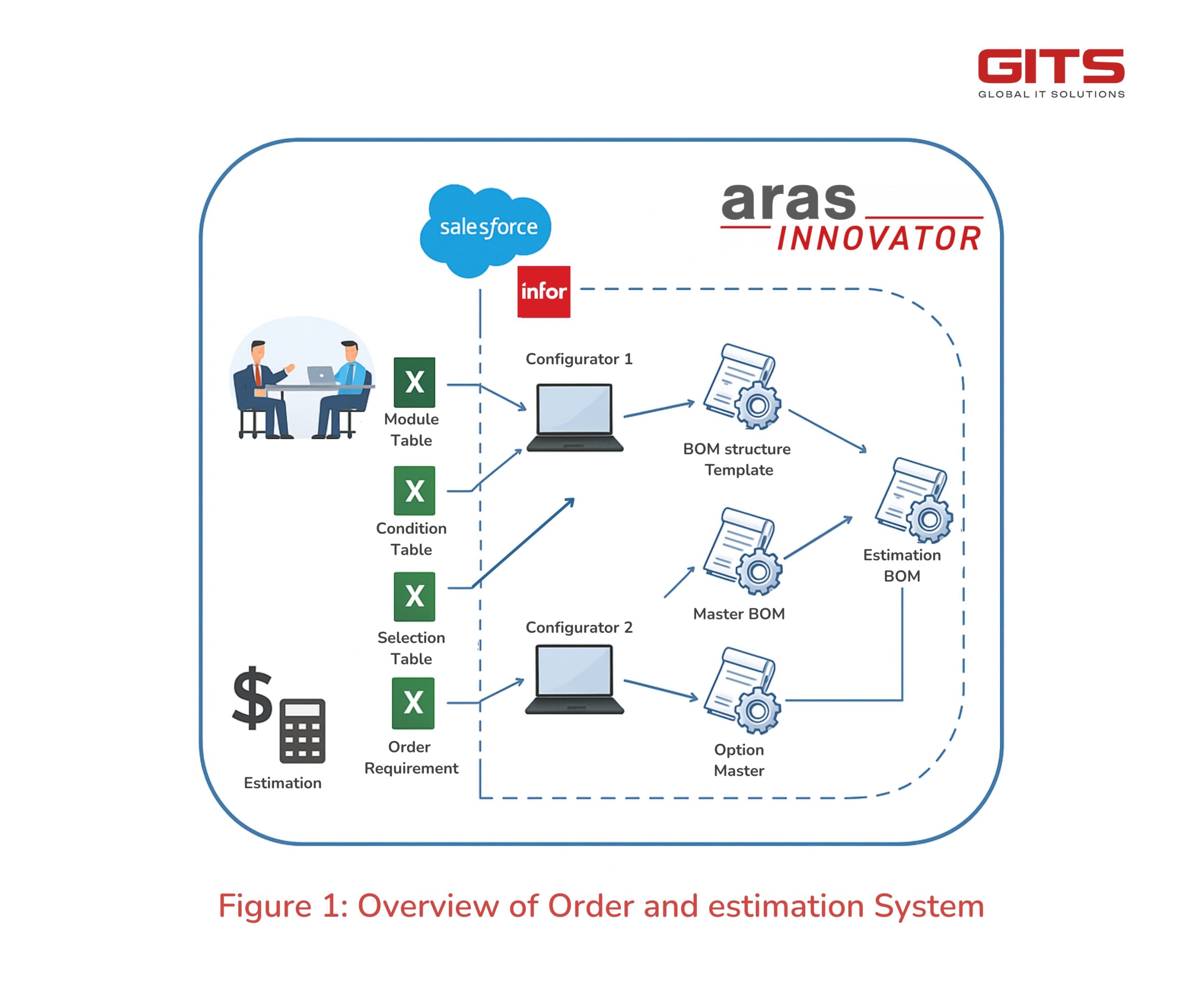

How it works: system architecture

The GITS PLM System integrates multiple components to create a seamless, automated, and data-driven manufacturing workflow:

- Salesforce integration – Automates order input and tracking.

- Excel-based configurators – Enables modular configuration management for better decision-making.

- BOM structure template – Ensures accuracy in material planning.

- Estimation & cost calculation – Automates pricing strategies to optimize profitability.

- Secure cloud infrastructure – Hosted on AWS for scalability and data security.

- Mobile application – Provides real-time monitoring and updates.

The impact: efficiency, cost savings, and business growth

Since implementing the GITS PLM System, the client has experienced significant operational improvements:

- 50% reduction in manual processes – Automation of workflows reduced errors and improved efficiency.

- 30% faster order processing – Streamlined digital workflows cut down processing times.

- Seamless scalability – The flexible system allows for future expansion and customization.

- Enhanced data security & compliance – AWS-backed cloud storage ensures regulatory compliance and prevents data breaches.

- Higher cost savings – By optimizing material management and pricing strategies, the client achieved greater cost efficiency.

Technologies behind the solution

To ensure a robust, scalable, and future-proof system, GITS utilized the latest technologies:

- ARAS Innovator – A flexible and highly customizable PLM platform.

- AWS (Amazon Web Services) – Secure cloud-based infrastructure for data storage and processing.

- Node.js – High-speed backend processing for efficient data handling.

- React.js – Intuitive and responsive web interface.

- Flutter – Cross-platform mobile application development.

Conclusion

By implementing a custom-built, cloud-based, and automated PLM system, GITS has helped the client reduce costs, enhance efficiency, and optimize product lifecycle management.

Are you looking to streamline your manufacturing operations with a scalable, cost-effective PLM solution? At GITS, we specialize in custom IT solutions tailored for manufacturing industries.

Contact us today to revolutionize your business with smart digital transformation!